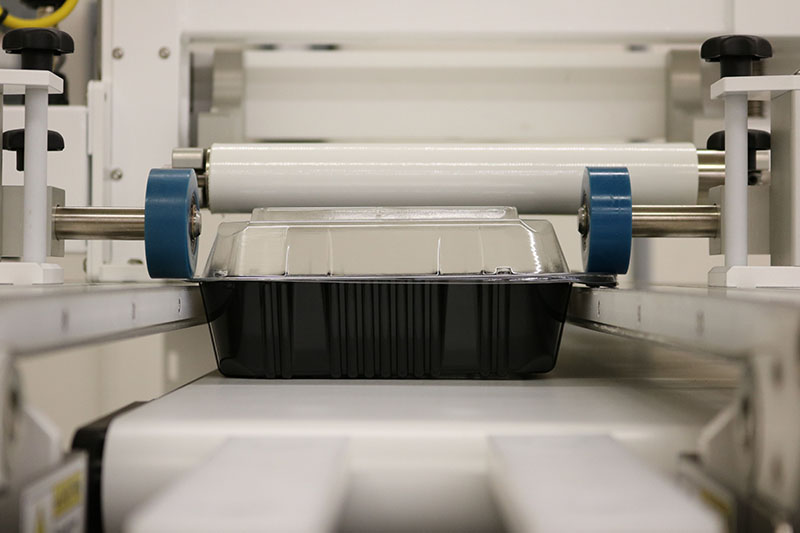

Clamshell Closure Machine

GPS’s flagship product is the Clamshell Closure Machine, or CCM. It is based on a proven design originally sold by our parent company, PMD.

After several service calls and spare parts orders for worn mechanical components, we began to ask some critical questions. Why are we seeing these problems? How can we avoid them altogether? Is there a better way?

We spent several months digging deep into the existing design. We reached out to you – our customers – and your input was invaluable. Your voices were heard.

The new CCM3000 still employs the original product’s four-conveyor design, which is the essence of its function. EVERYTHING else has changed. What was once a complex system of roller chains and pulleys became a direct drive motor for each of the three secondary conveyors, plus a single-belt drive for the main conveyor. The old tandem-wheel perimeter closers were simplified to a single idler wheel with 3 axes of easy adjustment. We even added a touchscreen user interface for quick and foolproof setup. This is linked to our new tandem motorized lifts to accommodate a wide range of package flange heights.

Throughout the entire redesign process, we did not lose sight of our customers and their industry-specific needs. All components of the CCM are rated IP66 or higher. They are completely sealed from particles and dust. The entire machine is safe for low-pressure washdown. Every component at or above the level of the main conveyor is FDA listed, so there’s no need to worry about incidental contact with your product. And the CCM’s power requirements have been reduced to 20 amps at 110VAC, so installation is as simple as plugging it in to any standard outlet.

Best of all, this feature-packed closure machine comes at a price almost 25 percent less than the previous generation.

For more information and technical specifications, the CCM brochure can be viewed here.

GPS ProSeal™ System

GPS ProSeal™ System seals a variety of material and bag types including, EX poly/poly, PET Laminates, Press to close, Slide-Rite advanced closure systems and standard open mouth bags.

The ProSeal™ is designed for portability allowing it to be located over an existing conveyor. It also incorporates height adjustment that enables the operator to set the elevation of the system to the surface of the conveyor. The panel mounted speed control allows the system to operate simultaneously with the conveyor. A pair of carrier belts guides the bag through the system holding it at the proper height for sealing as it passes between a set of heater bars.The hot seal then passes through a sealing wheel mounted on an adjustable pressure, linear motion air cylinder. The air pressure is adjusted through a regulator mounted below the control panel to the back of the system.

A set of infeed guide rails is utilized to properly locate the seal on the Slide-Rite advanced closure system to prevent damage while the sealing process is performed.

An optional Markum bag marking system can be located at the outlet of the system to mark the bags before they are discharged from the ProSeal™ system.