When it comes to high-volume manufacturing, value is a fact of life, quality is table stakes, and the ability to hit deadlines is paramount.

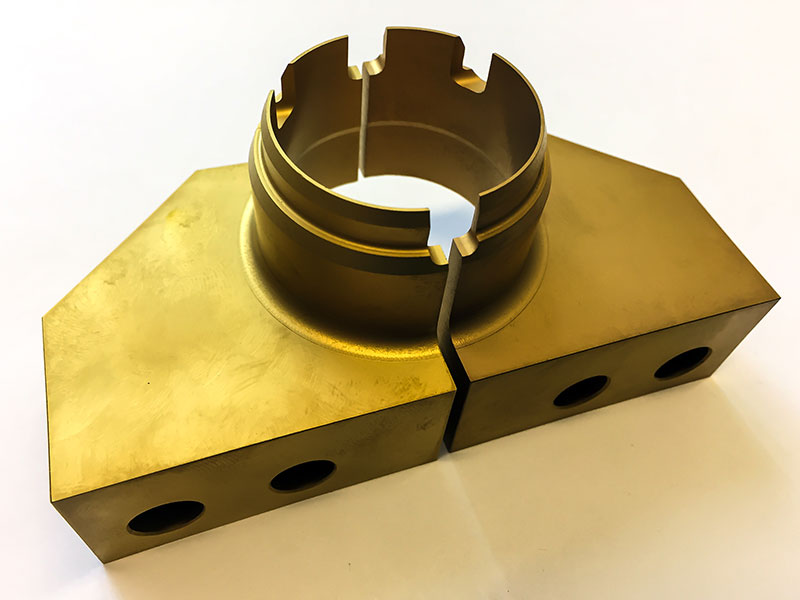

Our eleven vertical CNC machining centers and CNC lathe cell enable us to keep up with even the most demanding schedule, so you don’t have to miss a beat. Our speed and efficiency are second to none. We guarantee high tolerances and beautiful finishes right out of the machine – aluminum or steel, with no need for second operations. And when there is a need for high-tolerance finish operations, we rise to the challenge with our wire EDM and grinding capabilities.

To match up with customers who need short-run parts with a high level of quality, we have developed a tool room to drastically reduce lead times. It’s perfect for the efficient production of small quantities using high-tolerance milling, turning, and grinding.

Regardless of the manufacturing process, every batch of parts we produce is checked for 100% accuracy. Our quality assurance department is fully equipped with inspection equipment from micrometers to a fully-automated coordinate measuring machinery (CMM). At your request, we will provide you with inspection reports for any number of measurements you wish.

For more detailed information on our capabilities, please see our facilities list here.